General tolerances for form and position are valid for form elements for which form and position tolerances are not indicated individually. General tolerances for straightness and evenness in mm This tolerance principles says that no opposite relation between measure, form and position tolerance exists (principle of superposition).

#Iso 2768 mk e tabelle iso#

to ISO 8015 is valid and while this is mentioned in the drawing. General tolerances for form and position should be used while the tolerance principle according. Permissible deviations for linear dimensions except for external radii and chamfer heights. It is a very useful standard for buyers and suppliers. If smaller tolerances are needed or bigger are more economical these tolerances should be mentioned directly according to ISO 1101. DIN 7168 is a general tolerance standard for linear and angular dimensions, which could be widely used for inspection to cast iron and cast steel castings. The limit measurements of the tolerance classes m and f of DIN ISO 2768-1 are identic with those of DIN 7168-1.ĭIN ISO 2768-2 is for simplifying drawing and fixes general tolerances in three tolerance classes for form and position.īy choosing a special tolerance class exactly the precision level common in workshops should be taken into account. ISO 2768 – m or general tolerance ISO 2768 – mįor new designs only the general tolerance according to DIN ISO 2768-1 should be valid.

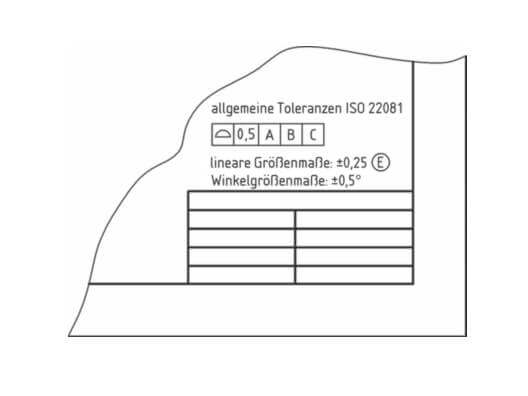

The following has to be inserted in the title box, i.e. If general tolerances according to ISO 2768-1 are valid,

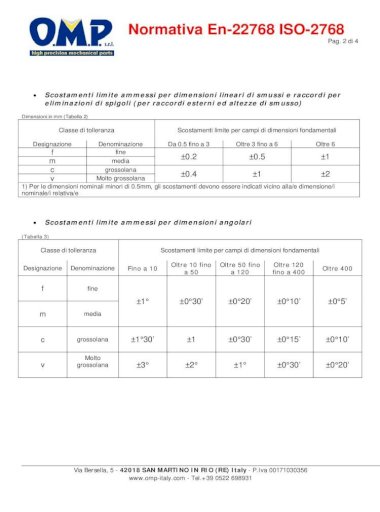

Tabelle 3 Grenzabmasse für Winkelmasse Tolerance classįor nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure.

Tabular 2 Limit measures for radius of curvature and chamfer height Toleranceīei Nennmassen unter 0,5 mm sind die Grenzabmasse direkt am Nennmass anzugeben. Tabular 1 Limits for linear measures Tolerance-įor nominal sizes below 0,5 mm the limit measures are to be indicated directly at the nominal measure. Then these tolerances are indicated next to the nominal size. If smaller tolerances are needed or bigger ones are more economical, If I find some time tomorrow, I will see if I can scan my tables and send them to you.General tolerances for linear measures and level squares with four tolerance classes are useful for simplifying drawings.īy choosing the tolerance class precision levels common in workshops should be taken into account. ISO 2768 consists of the following parts, under the general title General tolerances: Part 1: Tolerances for linear and angular dimensions without individual tolerance indications - Part 2: Geometrical tolerances for features without individual tolerance indi cations Annex A of this part of ISO 2768 is for information only. I wish I had a copy of the complete tables I could email you, the following link is mounting and dismounting catalog that has tables in the back, but does not have all of what you are looking for. It specifies general geometrical tolerances in three tolerance classes.

#Iso 2768 mk e tabelle plus#

Are you sure you are not looking at H tolerance tables? The capital H is for holes and all of those are 0 to a plus number.Īfter you have used it a bit, these tolerances get easier. This part of ISO 2768 is intended to simplify drawing indications and specifies general geometrical tolerances to control those features on the drawing which have no respective individual indication. The +43 on the h9 tolerance is definitely wrong, all the h tolerances are +0 and a negative number. I'm using a book published by FAG Bearings that lists the complete tolerance range for each designation, I don't have my Machinerys Handbook here to check and see what is in there. Bearing tolerances are usually fairly tight since that controls the amount of internal clearance of the rolling elements to the race of the bearing when installed.Īn M6 tolerance on a 47mm bore should be -4 to -20 according to my book.

0 kommentar(er)

0 kommentar(er)